Over-hypes In Ceramic Coating

Let’s discuss some of the over-hypes In ceramic coating in detail.

CERAMIC COATING OVER HYPES

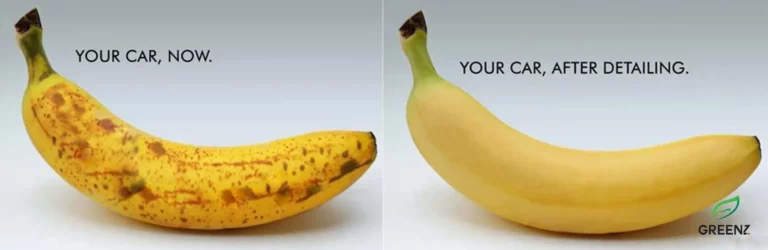

Ceramic coatings are now new trend in Detailing Industry, not just in India but across the world too. We, GreenZ Car Care introduced ceramic coating first time in India years back, but the situation has changed dramatically and the market is now flooded with “Anti-scratch” coatings and “Life-time” warranty coatings! So with this blog, we wanted to clear some confusions and over-hype created by those who wanted to utilize the situation and make a quick buck.

What’s Ceramic Coating?

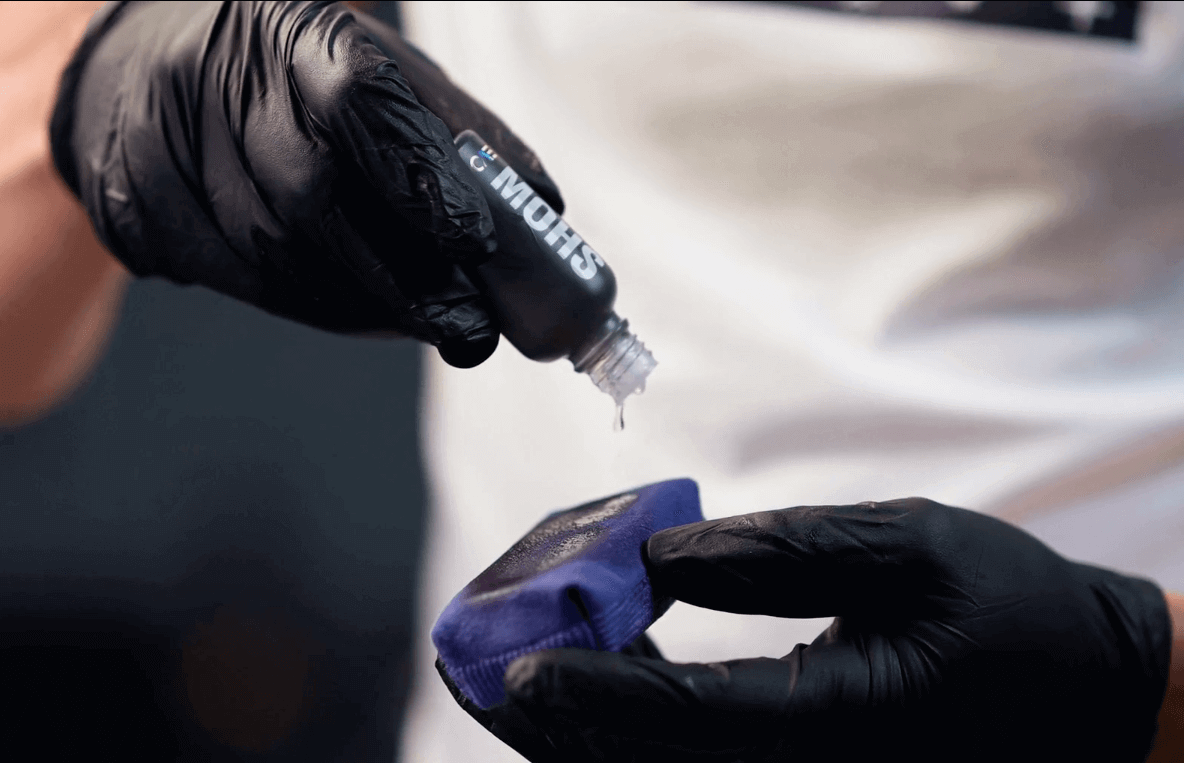

First, let’s understand what ceramic coating is? Ceramic coating is also called as Glass Coating, Quartz Coating and Nano Coating. Ceramic coating is a suspension of Silicon Oxide (SiO) in a proprietary resin that cures and oxidizes as Silicon Dioxide (SiO2). Silicon Dioxide has a Mohs (Mohs is a scale used to measure hardness) hardness of 7 and a melting point of 1610 degrees Celsius. Some coatings contain variations of polymers and Silicon Carbide (SiC) to alter the installation methods and hardness of the coating.

9H Hype

The hardness of a coating is measured in Mohs scale with pencil test, which was originally developed by pencil manufacturers as a quality control method in the early 1900’s.

The term “9H” is abused big-time these days by the ceramic coating brands, and many even have “9H” on their product name itself as a way to confuse and attract more customers. Most of these “9H” coatings offer “Life-time warranty” and “scratch-proofing” but severely failed to protect the paint from even swirls (swirls are circle like scratches seen on paint surface due to improper cleaning, please visit our car care guide for more details).

The 9H certificate for a coating is usually given by agencies like Korean Testing and Research Institute (KTR) and SGS Taiwan, which just prove that the tested coating product (if used properly with sufficient quantity and multiple layers) can achieve 9H hardness, that’s all. Which means that any kind of application will not be able to provide the same 9H hardness and a normal customer (even a detailer) never been able to verify the actual “hardness” he got from the coating.

Scratch, fire test and what not?

The gimmicks demonstrated by some coating installers, calling them coating installers not detailers because coating is just one of the option in Paint Protection stage of a complete detailing process (which consists of stages like Cleaning, De-Contamination, Paint Correction and Paint Protection) such as fire test, scratch test etc reminds you a magician not a detailer, this is nothing to do with the performance of a coating and most often done as a marketing gimmick.

What about Durability and Life-time Warranty?

These are another hypes created in the market, those brands introduced a year back in Indian market also claims “Life-time warranty” in Indian condition! A coating (or any paint protection) which can stay to maximum 2-3 years is ideal for Indian condition; paying anything beyond is non-practical in India.

8 to 12 Layers!

Before exposing the “Layer” scam, let me explain how coating will be working on the paint (or any) surface. After applying, coating bonds to the paint on a molecular level, forming a cross-linked covalent bond (hence it’s also called nano-coating) and the covalent bond is done on the electrons in the paint molecules. After 3-4 layers of coating, the available free electrons on the paint molecules will come down substantially which results no/less bonding thereafter and the 8-12 layer stories are just hypes which don’t offer any positive difference to the paint surface but negative impact on customer’s pocket!

So, What to be done?

Any coating which is not properly done or properly maintained will not last more than few months, so find a genuine detailer who uses the products and follows all the process religiously as suggested by the manufacturer and get your coatings done. Surface preparation is very important in coating and directly impact the durability of the coating.

Advantages of ceramic coatings

A properly applied ceramic coating can offer the following benefits:

- Excellent Durability of the Protection – Unlike other paint protection options (waxes or sealants), coatings offer more durability (in years)

- Measurable Thickness – Coatings can add few microns (thickness is measured in microns) to the paint surface and so most of the abuse it takes and may not go to the paint level.

- Hardness – Coatings are harder than any other paint protection options hence strong protection.

- Ease of Maintenance – The coated cars are easier to maintain as it will add dust & water repellent (hydrophobic) behaviour to the surface, which reduces the rate at which car gets dirtier.

- Resistant to Contamination – The coated car will have some resistance to the contamination like tree saps, bird poops, industrial pollution, tar contamination etc, it will be easy to clean them as well.

- High Gloss and Shine – The coated surface will become highly reflective and shiny, it adds immense gloss to the paint surface as well.

Please check our ceramic coating range which are genuine and we don’t do any over-hypes. Also check our blog on What is 9H Ceramic Coating?, What is 9H Hardness of Ceramic Coating, Fire Test – Marketing Gimmick In Ceramic Coating to know more about ceramic coatings and other over-hypes in it’s marketing.